The ultimate purpose of wall padding is to protect against serious injury if your athlete were to accidentally run, trip, stumble or collide into a hard surface such as a wall, door, stage or other obstacle. Without a protective layer of padding in place, a sudden impact could lead to a serious injury, potentially even fatal. Any facility where there are athletic events occurring i.e. gymnasium, field house, etc and the potential to run into a hard surface such as cement/cinder blocks exists, wall padding provides not just a necessary, but a critical layer of safety. Below are the 3 components of wall padding that are important to keep in mind when investing in you gym.

Wood Backing

A typical wall padding panel consists of a wood-based backing material, to which foam is adhered and covered with a vinyl fabric. All three components combine to provide a product that creates a necessary safety barrier anywhere a potential collision can occur. Each component provides a different functionality and depending on the facility in which the wall padding will be installed, it is essential to pick the best combination of materials to provide the most appropriate and best safety barrier.

The backer board component of wall padding provides structural support and creates aesthetic value in the final installed product. At Mancino, the preferred substrate is a minimum 7/16” thick OSB oriented strand board wood backing that is made from recycled composite wood that is SFI® Certified and urea formaldehyde free. A wood backed wall pad provides structural integrity which helps prevent the sagging that can occur over time with a non-wood backed hung padding.

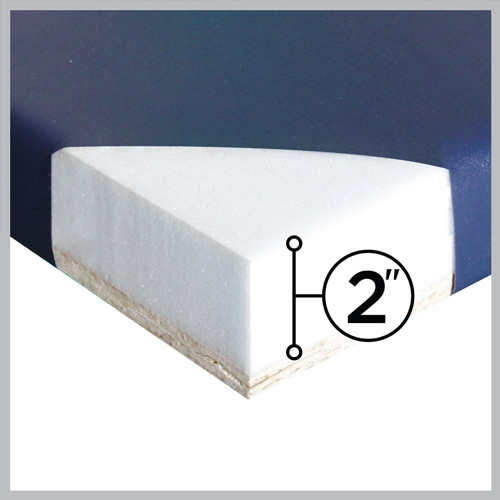

Foam

The second component, which makes up the interior of wall padding, is foam. Foam is adhered to the backer board with an adhesive. It provides the impact protection again collision forces. Wall padding is differentiated by the foam used. The differing types of foam dictate the amount of shock absorbing properties (impact attenuation) and the fire class rating it will have. Polyurethane based foams typically used in wall padding have an open cell structure and provide a softer feel. Polyethylene based foams used are closed cell giving a firmer feel and protect against higher impacts. In addition to the foam type, foam density, thickness and flame retardant properties can vary. Mancino provides a wide array of wall padding options each differing by the type of foam used. Please refer to the specification sheet for each series which can be found at the bottom of our wall padding section for more details.

Cover

The last component of wall padding is the protective covering material. Typical wall padding is covered with a knife-coated or a spray-coated vinyl material. In addition to providing aesthetic value, the covering contributes to the durability and longevity of the wall padding. Mancino Manufacturing uses a 16oz knife-coated vinyl. The importance of using a knife-coated vinyl over a spray-coated laminate type, is the increased abrasion and puncture resistance properties inherent to the material. Knife coating results in a thicker layer of vinyl coated material resulting in wall padding that can withstand a higher degree of trauma from repeated impacts to the surface or from increased stress points found at corners and bends. Abrasion studies of have shown that a 16oz knife-coated vinyl to be up to 3 times more abrasion resistant than a 14oz spray coated laminate type vinyl. In addition, due to the greater tensile strength inherent with knife-coated vinyl, it also allows for a wall pad that has better puncture resistance. The vinyl that Mancino Manufacturing uses to cover its wall padding also contains an anti-bacterial additive designed to prevent the growth and spread of mold, mildew and fungal bacteria. Especially beneficial in athletic or healthcare facilities where a hot and/or humid environment often exits, the protective treatment in wall padding creates an additional layer of safety.